Chemicals of concern (CoC) in the building and construction sector is not a new issue. Childhood lead poisoning and chronic lung disease from the inhalation of asbestos fibers are well-known impacts of chemicals that have afflicted the sector over the decades. Building and construction is one of the most chemical-intensive sectors downstream of the chemical industry and the largest end market for chemicals, generating the highest chemical revenue of all sectors. Driven by rapidly accelerating urbanization, the global construction sector is expected to grow by 3.5% annually, with its chemicals market growing by 6.2% annually between 2018 and 2023.

Compared to other consumer products, such as textiles, electronics, and toys, products for the building and construction sector are used solely in the built environment context and are directly linked to the life cycle of buildings, from manufacturing and construction, through the use phase to demolition, recycling, or disposal. In addition, a building’s life cycle can last for decades or centuries, longer than other sectors. This results in a greater lag time between the design and manufacturing stages and the end-of-life stages, during which knowledge about chemicals and their risks may increase, as can the health and environmental impacts. At the end of life, building and construction products enter the waste stream as construction and demolition waste, which often represents the largest proportion of total waste generated in a country and poses considerable risk if not properly managed.

Negotiations are underway to develop a new global framework for the sustainable management of chemicals and waste to succeed the Strategic Approach to International Chemicals Management (SAICM), which was established in 2006. Following a delay due to the COVID-19 pandemic, discussions on the Strategic Approach and the sound management of chemicals and waste beyond 2020 (Beyond 2020) are expected to result in an adopted framework at the fifth International Conference on Chemicals Management (ICCM5) in Bonn, Germany, in September 2023. Managing chemicals in products, which includes the building and construction sector, is expected to be an integral part of the new framework.

This policy brief explores efforts and initiatives to advance the issue of CoC in the building and construction sector, including under a GEF-funded project on Global Best Practices on Emerging Chemical Policy Issues of Concern under SAICM, launched in 2019. The project focuses on lead in paint and chemicals in products such as electronics, toys, and building and construction, as well as on knowledge and stakeholder engagement. The brief draws on a 2021 SAICM report on the building and construction sector, which recommends, inter alia, more circularity and a life-cycle approach in the sector, and highlights opportunities for the sector that ICCM5 and the Beyond 2020 framework provides. It also discusses a proposal regarding a sectoral approach for implementation when addressing CoC in products that was tabled by the Inter-Organization Programme for the Sound Management of Chemicals (IOMC) for inclusion in the Beyond 2020 framework instrument.

What are chemicals of concern in the building and construction sector?

A range of chemicals have been and continue to be used in building and construction products in everything from insulation materials and sealants to paint, wood products, and carpeting. Building materials and construction activities use petrochemicals, industrial gases, and specialty chemicals, such as concrete admixtures, flame retardants, coatings, and adhesives, among others. Chemicals used in building materials can also be a passive emission source indoors, leading to deteriorating indoor environmental quality. As a result, some chemicals have been banned or have extremely restricted use, while others have risks of concern with knowledge and evidence still emerging. Asbestos, lead in paint used in buildings, brominated flame retardants and PFAS (per- and poly-fluoroalkyl substances, or “forever chemicals”) are some of the better-known ones. International efforts to ban and restrict their use have had some significant successes, although much remains to be done.

For example, beginning in the late 19th and early 20th century, asbestos was considered an ideal material for use in the construction industry because it could act as a fire retardant with high electrical resistance and was inexpensive and easy to use. Efforts to limit its use began in the 1970s when its toxicity and related health impacts became better known. When asbestos fibers become airborne and are inhaled, they cannot be expelled by the lungs due to their size. They are also sharp and penetrate internal tissues. The World Health Organization (WHO) lists asbestos as a serious carcinogen. It causes a range of diseases from breathing difficulties and lung disease to cancers of the stomach, ovaries, and kidneys.

Although relatively safe while encapsulated in glue or cement, asbestos becomes hazardous when the buildings are destroyed or torn down and it is released into the air. A recent example of this is in Ukraine, where many buildings built using asbestos have been destroyed during the ongoing war, creating millions of tons of highly hazardous, asbestos-contaminated rubble, constituting a long-term health hazard. Asbestos is listed as a category of controlled waste under Annex I of the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal, with exemptions for minor uses permitted in some countries. Even though worldwide more than 67 countries have banned the use of asbestos, many others have yet to ban its use, and even in countries where it is banned, asbestos remains in the buildings for decades and sometimes centuries. It is thus a “legacy” chemical, an issue that must be addressed.

Lead is another CoC in the building sector, used as a paint additive. Lead can cause brain damage, particularly in children, and damage kidneys, nerves, and blood, especially because of deteriorating lead-based paint that is peeling, chipping, chalking, cracking, or damp, and can enter the body through inhalation, ingestion, or dermal contact. Most developed countries banned decorative lead paint over 40 years ago, adopting regulations to control lead in paints used in homes, schools, and other buildings. However, studies conducted by the International Pollutants Elimination Network (IPEN) in more than 55 countries found that high lead levels in paint still exist in most of them. In the US, for example, although lead-based paint was banned for residential use in 1978, it remains a legacy chemical due to its presence in millions of homes built before 1978 and continues to be a leading cause of childhood lead poisoning.

The Global Alliance to Eliminate Lead in Paint, jointly led by the WHO and the UN Environment Programme (UNEP), helps prevent exposure to lead by promoting the phase-out of paints containing lead and helping countries pass legislation based on the Alliance’s Model Law and Guidance for Regulating Lead in Paint. According to the WHO Global Health Observatory on legally-binding controls on lead paint, as of 31 March 2023, 48% of countries reported that they have legally binding controls on the production, import, sale, and use of lead paints. Nonetheless, paints with lead are still sold in many low- and middle-income countries (LMICs), including in Eastern Europe and Central Asia. At the end of 2022, according to UNEP, more than 100 countries still had not set legal limits on lead in paint.

While lead and asbestos and their impacts have historically garnered much publicity, brominated flame-retardants (BFRs) and PFAS have more recently come to the fore, raising alarms. PFAS, for example, are used in building and construction materials, such as electrical wires and cables, thermal insulation foams, stain- and water-resistant carpeting, and paints, adhesives, and sealants for waterproofing. First used in the 1940s, they are now present in hundreds of products, and have been linked to endocrine disruption, thyroid disease, neurological and liver damage, and cancer. Because they break down very slowly, persist in the environment, are “nearly indestructible,” and resist grease, oil, water, and heat, they are commonly referred to as “forever chemicals.” BRFs, a relatively new generation of chemicals used as flame retardants, are still widely used in industrialized countries, although some are voluntarily banned by manufacturers. Currently, BFRs and PFAS are being addressed in some manner under the Stockholm Convention on Persistent Organic Pollutants (POPs). For example, most commercial PFAS and BFRs are listed in the Stockholm Convention with restrictions on their production and use. Nevertheless, exemptions exist which allows them to be used in some building and construction products, for example, use of deca-BDE in polyurethane foam for insulation.

While these examples illustrate targeted efforts to ban or restrict use of specific chemicals, a holistic, sector-wide approach is also necessary to tackle CoC in the building and construction sector more broadly. Sectoral policies, for example, can provide an opportunity to chart the path forward towards addressing CoC in the sector and achieving sustainable development more broadly.

Initiatives to address chemicals of concern in building and construction

SAICM is at the forefront of international action to address CoC in products, including those in the building and construction sector. Chemicals in products and lead in paint are longstanding emerging policy issues (EPIs) and other issues of concern under SAICM. From 2020-2022, SAICM convened multiple Communities of Practice, which held discussions on these issues among interested and relevant stakeholders. The Chemicals in Products Community of Practice discussed, among others, CoC in building materials.

UNEP’s Eco-Innovation Manual and its building materials supplement presents the eco-innovation process through the example of a fictional company, elucidating the many innovations the sector could potentially take to transition to a pathway that is better for both human health and the environment. UNEP’s Chemicals in Products (CiP) Programme is a voluntary initiative designed to help all stakeholders who are seeking to improve the process for exchanging information on chemicals in products throughout their life cycle. It focuses on the four priority sectors of electronics, building products, toys, and textiles. In addition, the GEF’s Eighth Replenishment (GEF-8) Programming Directions include a Sustainable Cities Integrated Program that highlights the construction sector’s contribution to mercury emissions from cement production. It, thus, promotes circularity and integrated approaches in this regard. The Program will also support improved landfill management and increased energy efficiency in buildings and lighting systems, which can contribute to the reduction of hazardous chemicals, including POPs and mercury.

SAICM’s Buildings InfoHub provides information and resources for designers, architects, builders, and other actors in the construction value chain to help understand, identify, and reduce risks and impacts of chemicals in building materials. It details some of the chemical hazards in common building materials and products, such as: adhesives, sealants, and waterproofing; plastics; flooring; insulation; paints and coatings; and roofing. It also contains guidance and tools to conduct chemicals assessments at different stages of the value chain, as well as assess hazards. A chemical substitutes and alternatives page details key considerations to avoid “regrettable substitution” (when one chemical is replaced by another that is just as harmful or worse).

The InfoHub highlights policies from around the world that aim to phase out harmful chemicals in the sector and help transform markets towards safer alternatives, including those related to global chemicals inventories, cleaning up “forever chemicals” in construction, and action on asbestos and lead. Case studies spotlight best practice examples of various approaches to managing CoCs in the building and construction sector, including affordable housing developments in New York City and Minnesota, US, using materials that take human health impacts into consideration. The InfoHub also links to global databases of building products, which have been assessed against sustainability certifications or other chemicals-related criteria.

UNEP Report on Chemicals of Concern in the Building and Construction Sector

UNEP’s technical report on Chemicals of Concern in the Building and Construction Sector, developed within the framework of the GEF project on Global Best Practices on Emerging Chemical Policy Issues of Concern under SAICM, provides an overview of the challenges that CoC pose in the context of products in the sector. The 2021 report: identifies and elaborates on 30 CoC; outlines linkages among CoC with respect to the building life cycle; and highlights existing gaps, challenges, and opportunities regarding increasing circularity in the sector.

The sector is one of the largest end markets for chemicals and its product range reflects the full diversity of outputs from the chemical industry, according to the report. One chemical may be used in multiple applications throughout the sector, affecting different stakeholders, and at different stages in the process. For example, certain short-chain chlorinated paraffins (SCCPs), addressed under the Stockholm Convention, could be used as plasticizers in flexible PVC material used for wood panel ceilings, flooring, or in plumbing, but also as flame retardants in paints for metal surfaces or interior walls.

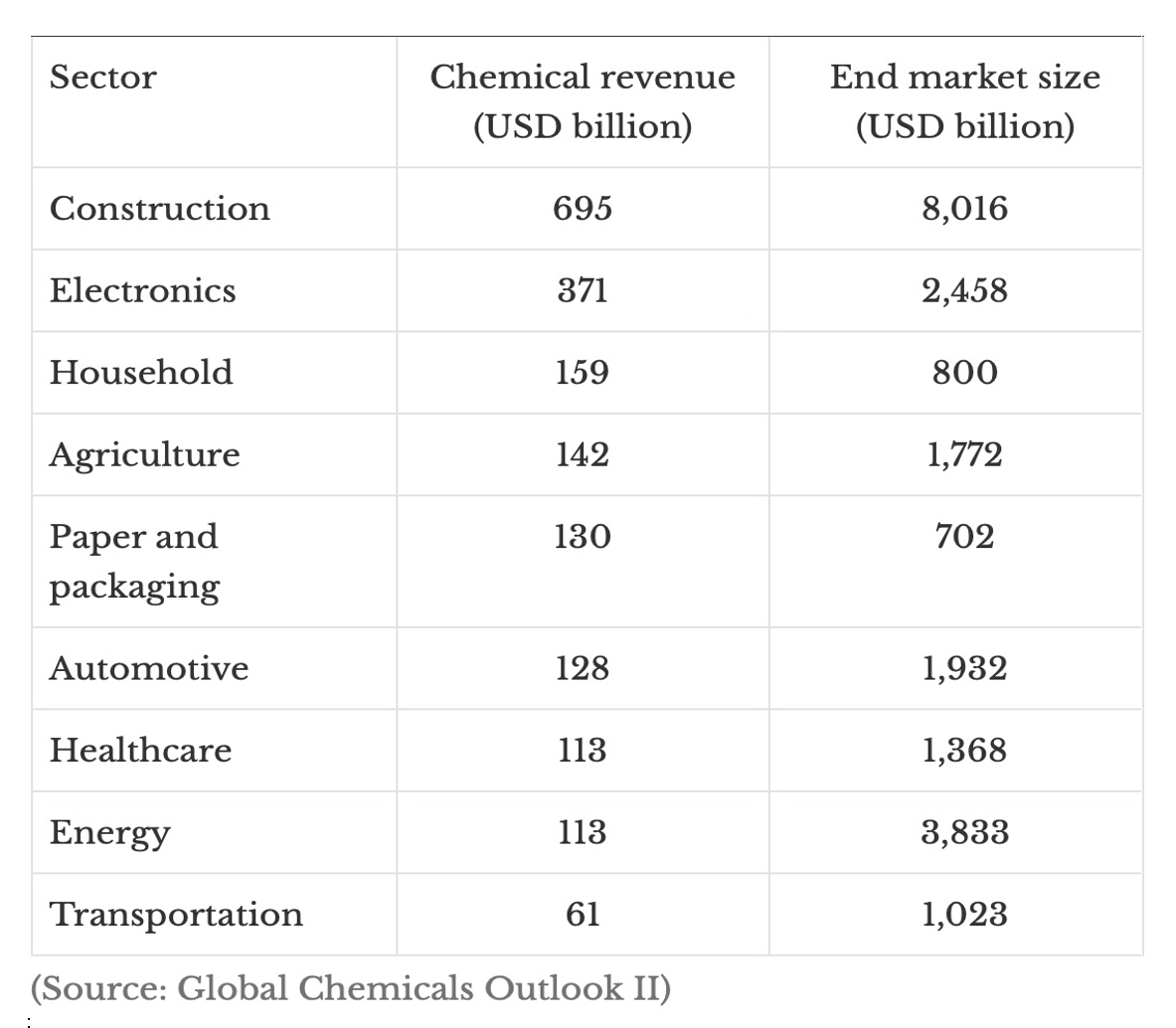

Table 1: Chemical Revenues by Sector and End-Market Size

Given the considerable lag between the design and manufacturing and end-of-life stages of building and construction products, by the time risk management action is taken for a CoC, the chemical has already been used in products and sold on markets sometimes for extended periods of time, the report states. Legacy chemicals are, therefore, important to consider when discussing CoC in building products. For example, use of polychlorinated biphenyls (PCBs) in Switzerland was widespread in coatings and joint sealants but was banned in 1972. The report flags that due to the long lifetime of these products in the built environment, PCBs are still routinely found in buildings during refurbishing or demolition operations more than 50 years after they were banned.

At the end of life, the report notes, building and construction products enter the waste stream as construction or demolition waste, which may be considered hazardous at the national or international levels, such as under the Basel Convention. Such waste often represents the largest proportion of total waste generated in a country and is only growing due to the increase in infrastructure development across the globe. In the EU, for example, construction and demolition waste accounts for more than one-third of all waste generated.

Despite this, the report explains, the building and construction sector represents significant opportunities for sustainable development, given the sector’s growth trajectory. It recommends adopting a more holistic approach, which combines addressing legacy chemicals with innovations in chemistry and material science, design practices, and regulation to increase chemical safety, reduce hazards, and increase resource efficiency. Beyond SDG targets directly relevant to chemicals and waste, such as SDG target 12.4 (on achieving the environmentally sound management of chemicals and all wastes throughout their life cycle) and SDG target 3.9 (on reducing the number of deaths and illnesses from hazardous chemicals), all 17 SDGs can be supported through the sound chemicals and waste management.

The report underscores the need for more research and collaboration to address emerging concerns about additional chemicals in the sector. It urges adopting a precautionary approach where evidence is emerging, or where data gaps exist on hazards and potential impacts.

Opportunities and recommendations detailed in the report revolve around the following:

- Increasing information transparency on chemicals and ensuring the flow of information along the entire life cycle of building products. As information on use and concentration levels is still scarce, action on increasing transparency could build on existing initiatives, such as health product declarations developed under voluntary building certification schemes (e.g., Leadership and Energy Environmental Design, or LEED) or databases providing occupational safety information for construction workers, such as the German GISBAU initiative. Furthermore, available information on CoC uses in building products often reflects the context of their application in specific products and industries in developed countries, as well as the identification of potential risk. Thus, the current results and available knowledge might not fully reflect the situation in developing countries and economies in transition.

- Designing new buildings for circularity and using products that support the sector’s transition to circular models and retain the highest possible value at the end of life. Potential chemicals-related impacts of materials along the entire life cycle of buildings should be evaluated, and benign chemicals and recyclable materials should be developed through green and sustainable chemistry innovation. When CoC cannot be avoided, contaminated materials should be separated from uncontaminated materials at the end of life.

- Minimizing the impacts of legacy chemicals and barriers to circularity for existing buildings and developing new technologies for recycling. Barriers in the context of legacy chemicals should be addressed, for example, by managing construction and demolition waste containing CoC, such as POPs, in as sound a manner as possible to minimize their negative impacts. Efforts should also be made to avoid reintroducing CoC into secondary raw materials, and to advance research and development of technologies for the sound recycling of building products that contain CoC.

- Undertaking targeted regulatory action to identify, assess, and address CoC in building products, based on emerging scientific knowledge, to ensure protection of human health and the environment at all stages of the life cycle. This could include advancing knowledge on applications and potential occurrences of identified CoCs, such as POPs, in products relevant to the sector, as well as mandating and incentivizing phaseouts of individual CoC from products. Where substitution of CoC is not technically feasible, regulators must ensure adequate training and protection of, for example, construction workers and the general public. In addition, regulators should evaluate if regulatory requirements for the building and construction sector may have consequences for chemical use or material choices that, in turn, can cause adverse effects on human health or the environment.

IOMC proposal for the Beyond 2020 framework

In an effort to operationalize some of these recommendations going forward, the IOMC has proposed three Implementation Programmes for the Beyond 2020 framework that adopt a sectoral and value chain approach to chemicals and waste management more broadly to improve circularity. The proposal calls for:

- developing integrated national chemical management systems and capacities in all countries and regions;

- integrating sound chemicals and waste management in chemical-intensive economic sectors and value chains (which the building and construction sector falls under); and

- integrating sound chemicals and waste management within sustainable development objectives and decision-making processes.

The Programmes would aim to strengthen implementation of the Beyond 2020 framework through inclusive stakeholder and sectoral engagement and action, knowledge sharing, multi-stakeholder collaboration, and mobilization of additional resources. The Implementation Programmes would directly link to, and support implementation of, the proposed strategic objective and targets of the framework. They are also consistent with the three dimensions of integrated chemicals and waste management presented by the IOMC at the fourth meeting of the intersessional process considering the Strategic Approach and sound management of chemicals and waste beyond 2020 (IP4) in the fall of 2022.

To advance and inform about its ideas and proposal, the IOMC organized two workshops on advancing global chemicals and waste management in chemical-intensive economic sectors and value chains and industries. In January 2023, building and construction was discussed as a candidate sector for implementation. In June, discussions addressed guidance to support strategies and a possible global programme on advancing chemicals and waste management in economic industry sectors and their value chains.

Going Beyond 2020

We now know that business-as-usual in the building and construction sector is not an option. Whether it is managing legacy chemicals or integrating into products, from the beginning, materials that are better for the environment and human health, transitioning towards safety, sustainability, and circularity along the entire life cycle of the sector is crucial. Advancing and implementing recommendations outlined in this Policy Brief could help ensure the sector provides a meaningful contribution to the sound management of chemicals and waste in the Beyond 2020 framework, and to sustainable development more broadly.

* * *

This document has been developed within the framework of the Global Environment Facility (GEF) project ID: 9771 on Global Best Practices on Emerging Chemical Policy Issues of Concern under the Strategic Approach to International Chemicals Management (SAICM). This project is funded by the GEF, implemented by UNEP, and executed by the SAICM Secretariat. The International Institute for Sustainable Development acknowledges the financial contribution of the GEF to the development of this policy brief.

This Policy Brief is the eighth in a series featuring cross-cutting topics relating to the sound management of chemicals and waste. It was written by Leila Mead, Earth Negotiations Bulletin (ENB) team leader, editor, and writer. The series editor is Elena Kosolapova, Senior Policy Advisor, Tracking Progress Program, IISD.